1. Raw Material Preparation

Our raw material, we used the plastic resin grade A. We prepared the plastic resin in to the tank for mixing with additives ;

such as additional colour or anti static to increase specific qualifications which followed by customer orderd.

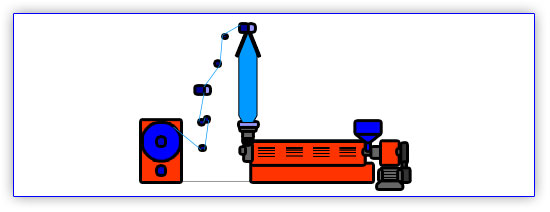

2. Extrusion Process

After prepared raw materials, then we have to send its into the Extrusion Machine which using high temperature and shear

stress to dissolve the plastic resins, then extrude through ringed die. Inside is air pressure is used to blow the plastic into tubular

formation pass air sharp upper and squeeze down to air sharp for making its to the plastic roll.

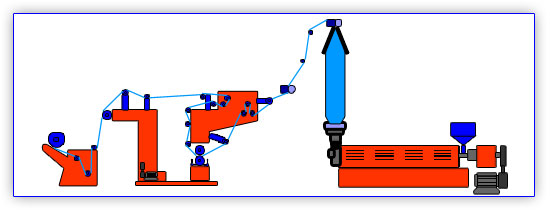

3. Printing Process

We used the Gravure Printing Machine to connect to the Extrusion Machine in step tubular formation, then will send the blown

molding film put into a printing by screen blocks to print out each primary color or pictures pass to and squeeze to air sharp for

making its to the plastic roll.

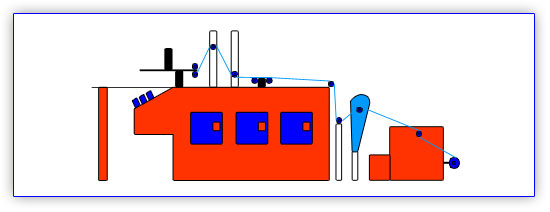

4. Cutting Process

The plastic roll will be next to the plastic bags on which there must be put into the sealed and cutting machine with heat and

the lenght cut according to the specification. This includes making holes and/or the bag's holders. Finally, the product is packed

in the designated quantity.